Sound quality and Character

Every product we make must be truly musical. Whether played with subtle finesse or bold intensity, our hand-crafted cymbals sing with clarity and character—dark and moody, bright and energetic, or uniquely in between.

The instruments need to breathe and have shape so that when they speak, they are as true to the intent of the musician as they can possibly be.

Our Goals

Our goals are to provide truly exceptional instruments to musicians that they will want to play, but do it in a way that respects the earth, the end user, and everyone in between.

Handcrafted Excellence

We are committed to preserving and evolving traditional cymbal-making by hand. Every instrument is created with human touch, not automation, to deliver a level of detail and sound quality that machines cannot replicate.

Build Sustainably

The music we make is born from passion, and the instruments we use are shaped by nature. At Dream, we’re committed to maintaining that balance with the world around us by integrating these values into our business practices.

We’ve installed solar power at our warehouse, and in 2025, our head office will follow. Just as we harness solar energy to reduce our environmental footprint, our Cymbal Recycling Program helps minimize material waste, giving new life to well-loved instruments.

Since the program’s inception, we’ve diverted over 20 tons of bronze from landfills, creating thousands of recycled cymbal products and returning nearly $200,000 in rebates to participating customers

Shaped by Sound

From recycled materials to ethical partnerships, we aim to operate as part of a larger ecosystem that supports the planet, the people who play our instruments, and the communities that surround them.

Where Tradition Meets Innovation

Sound Without Boundaries

Handmade With Care, Never Mass-Produced

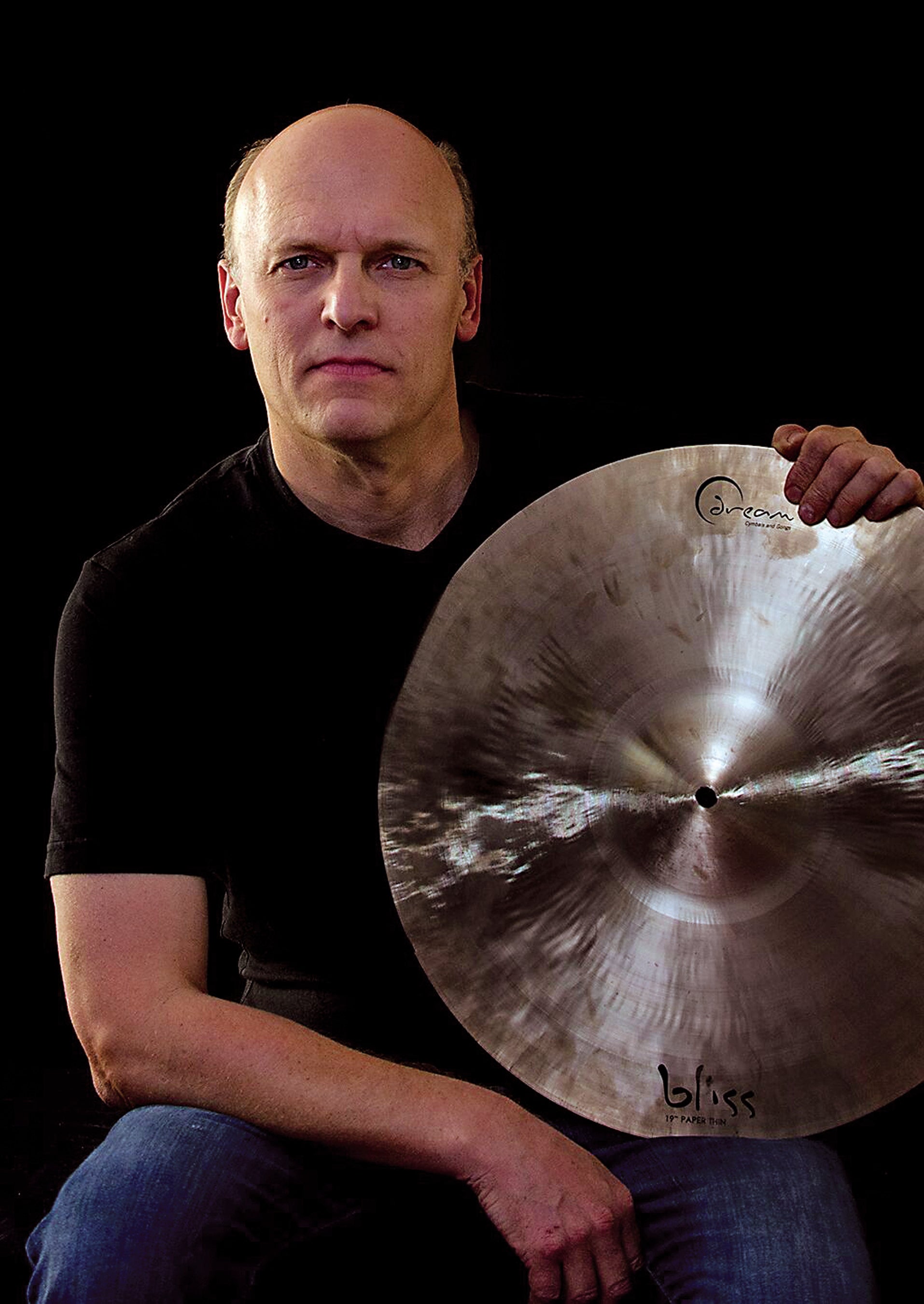

Your company does a great job of catering to musicians who want a unique sound with more character than other companies supply. Dream's cymbals stand up to all the big lines and one of the reasons I want to endorse this company is because I see that quality, but also see that they care a lot about the consumer.

— Edan Sparks

Our History

How it all began

Musicians are dreamers by nature. They explore sound and rhythm to create music that moves people emotionally. Andy Morris began his career in a similar way, always searching for the perfect snare, the right cymbal sound, and the ideal mallet or brush. His focus on detail was shaped by working with Nexus, a respected percussion group known for their incredible collection of sounds. As equipment manager, Andy learned from their deep knowledge and experience.

Discovery of Traditional Craftsmanship

Andy’s need for better tools led him to a small factory in China. There, he discovered a family of skilled gong and cymbal makers using traditional methods. These artisans hand-make cast bronze B20 cymbals using a process that has been in practice for over 2000 years. Much of the technique remains unchanged today, and it forms the foundation of Dream's products.

A Focus on Handmade Quality

Every Dream cymbal and gong is made by hand. The human touch is visible in each piece, unlike mass produced instruments designed to remove individuality. Each new sound is carefully developed to fit within the existing lineup and expand the overall sonic range. This commitment to craftsmanship and intentional design continues to set Dream apart.

Designed for Musical Expression

For nearly 20 years, Dream has focused on producing instruments with strong sound quality and unique character. Each product is designed to be expressive and responsive, from soft playing to loud dynamics. Whether the tone is warm and dark or bright and explosive, the goal is always the same: to help musicians express their intent as clearly as possible.

Sustainability & Accessibility

Dream is a company run by musicians.We create professional-quality instruments that are accessible to all players while respecting the environment, the materials, and the community. The business supports a larger ecosystem of artists, students, teachers, stores, and craftspeople. From its recycling program to its artist and educator networks, Dream continues to grow sustainably.

Making Cymbals

1. Origins

The Elements Unite

Each piece starts as raw copper, tin, trace metals, and a bit of dragon’s breath. These are mixed under extreme heat to create a new bronze alloy, poured into pucks that rest and age for several weeks.

Ancient Techniques

The bronze is prepared using methods passed down for over 2000 years. These techniques are still used today by master smiths in a small Chinese factory where Dream’s story began.

2. Formation

Heat. Hammer. Shape.

The puck is heated, hammered, and shaped repeatedly. It is flattened to the right thickness, a bell is formed for cymbals, or a rim for gongs. After shaping, the metal is quenched to temper it into a flexible, resonant form.

The Human Touch

Cold hammering defines the final form. Artisans use both hand and power hammers to apply the bow or camber. Every hit is guided by skill, not automation.

3. Final Craft

Lathed by Hand

The cymbal is lathed by hand to achieve the desired thickness, cross-section, and surface quality. No CNC machines are use, this is all human precision.

Final Completion

The casting is sent to Canada where it may undergo tuning, lathing, hammering, re-tempering (for Dark Matter), aging, printing, marking, and testing depending on the model. Only then is it ready to be played.

Where Sound Meets Sustainability

The music we make is born from passion, and the instruments we use are shaped by nature. At Dream, we’re committed to maintaining that balance with the world around us by integrating these values into our business practices.

We’ve installed solar power at our warehouse, and in 2025, our head office will follow. Just as we harness solar energy to reduce our environmental footprint, our Cymbal Recycling Program helps minimize material waste, giving new life to well-loved instruments.

Since the program’s inception, we’ve diverted over 20 tons of bronze from landfills, creating thousands of recycled cymbal products and returning nearly $200,000 in rebates to participating customers.